Overland conveyor

The overland belt conveyor is a continuous conveying apparatus that employs a conveyor belt as its traction and load-bearing component, facilitating the transportation of materials via the controlled motion of said conveyor belt.

Corrugated Ribbed Belt Conveyor

The corrugated ribbed belt conveyor is primarily utilized for the uninterrupted transportation of bulk materials at significant inclinations. It employs a conveyor belt featuring corrugated ribs and transverse partitions, allowing for conveying angles ranging from 0 to 90 degrees.

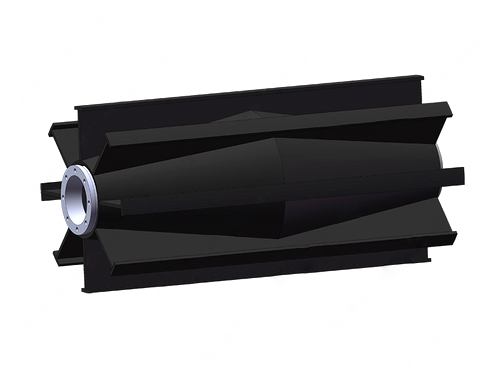

Tubular Belt Conveyor

The tubular belt conveyor comprises a configuration of sectioned six-sided layout edge roller tapes that are skillfully wrapped in overlapping fashion, forming a circular tubular structure for the transportation of materials. This innovative design represents a new paradigm in belt conveyor technology.

Mobile Belt Conveyor (Stacker)

The lower section of the mobile belt conveyor is equipped with a set of universal wheels, enabling effortless mobility based on the material stacking requirements. Furthermore, it offers the flexibility to adjust its height within the designated range.

.

Conveyor idler

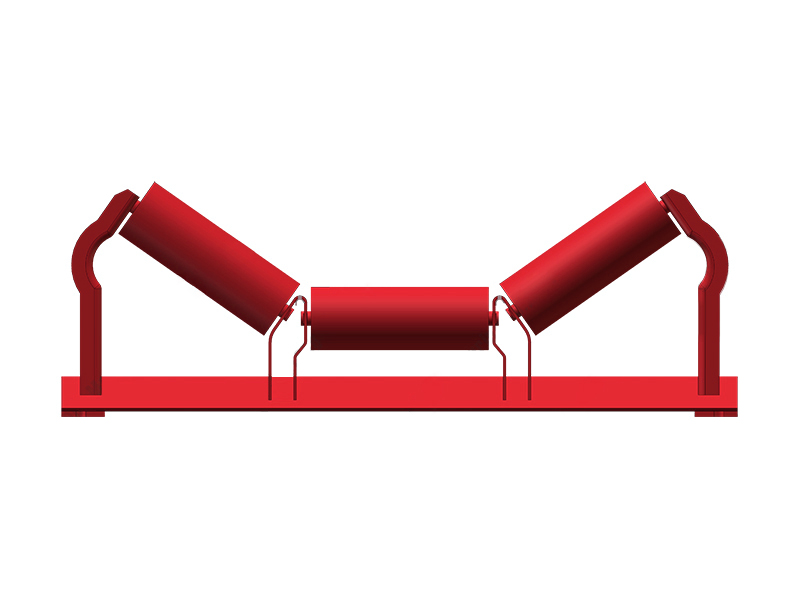

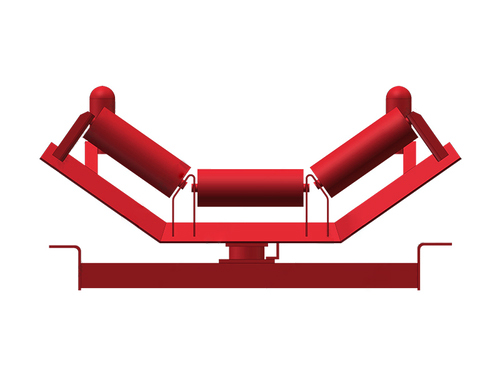

Troughed Idler

Troudhed Idler is a crucial component utilized for providing support to both the belt and the material being transported on the conveyor system. Typically, the standard trough angles are classified into the following divisions: 10°, 20°, 30°, 35°, and 45°.

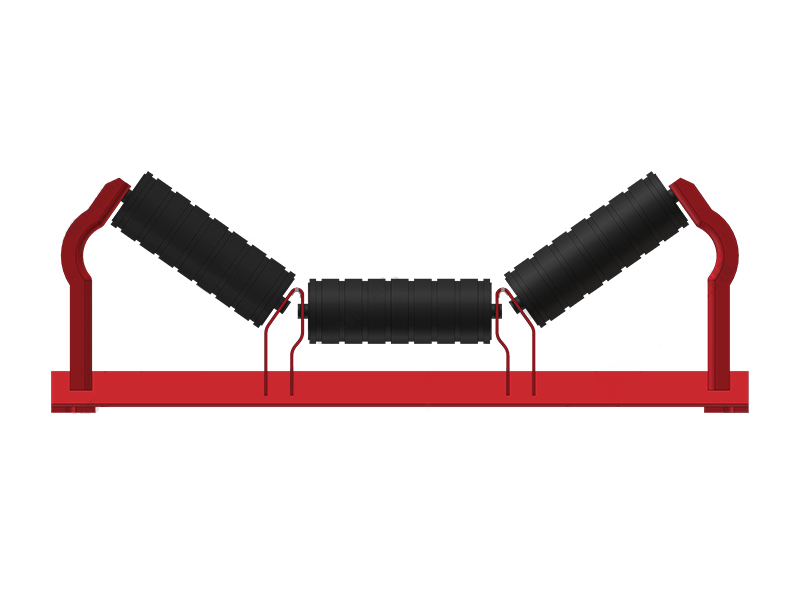

Impact Idler

The impact roller is strategically positioned beneath the drop material section of the conveyor, serving the purpose of mitigating the impact caused by the descending material on the conveyor belt. This proactive measure effectively extends the operational lifespan of the conveyor belt.

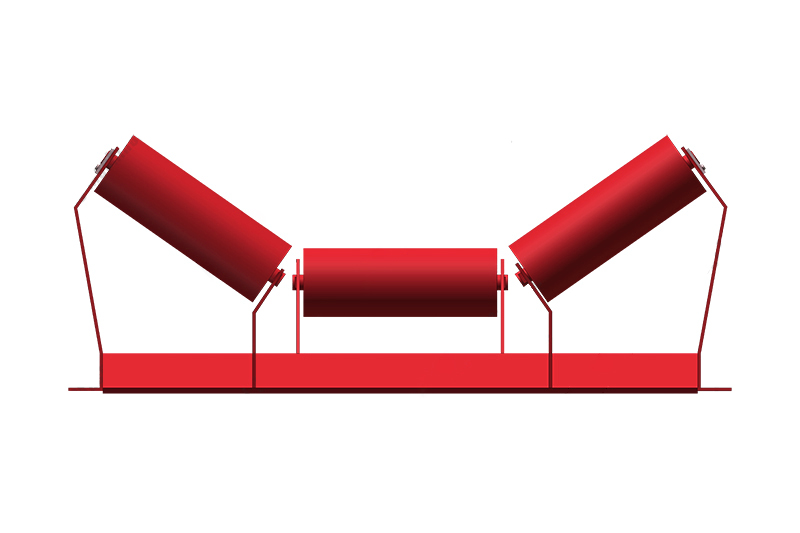

Offset Idler

The offset roller features a meticulously engineered design that incorporates an offset center roller configuration. This sophisticated design effectively eradicates roller gaps, mitigates belt pinch points, and significantly minimizes the likelihood of subsequent belt damage.

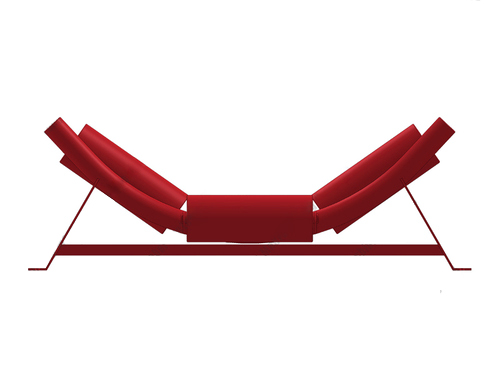

V-Type Return Idler

The V-type return roller primarily serves the critical function of providing support to the return section of the conveyor belt, effectively preventing any deviation in its operational trajectory.

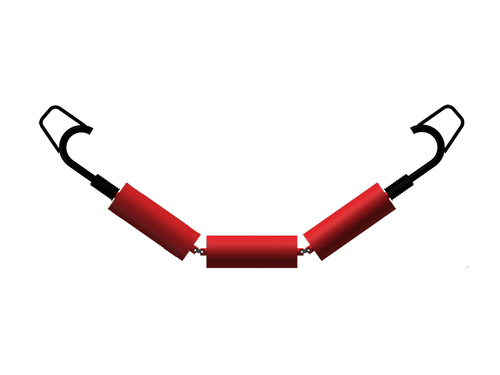

Garland Idler

The garland roller consists of a series of either 3-roller or 5-roller units, expertly interconnected at the ends of their respective shafts using specially designed lugs. This arrangement seamlessly forms a continuous “chain” of rollers. At both ends of this interconnected chain, the shafts are securely connected to an attachment bracket, enabling the complete roller set to be easily affixed to the conveyor stringer structures.

Wing Type Idler

Wing rollers are essential components frequently found in European-designed track-mounted crushers and various small-scale processing equipment. These rollers are designed to facilitate easy replacement of individual segments within the roller set, encompassing both the rollers themselves and the center stands, thereby providing customers with enhanced flexibility and maintenance capabilities.

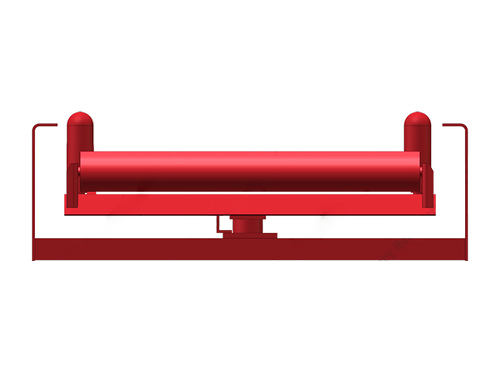

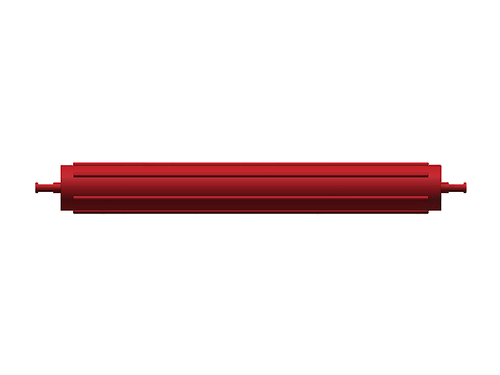

Steel Return Roller

The return roller plays a pivotal role in providing steadfast support to the conveyor belt within the return section, ensuring optimal functionality and operational efficiency.

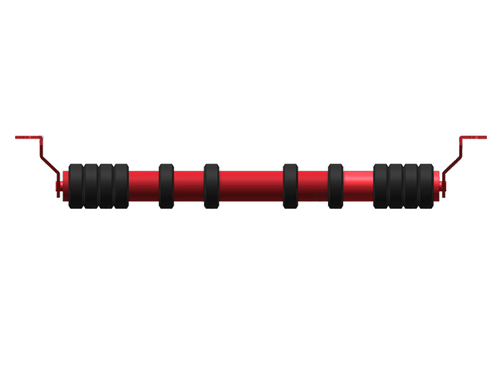

Rubber Disc Return Roller

The rubber disc return roller is strategically employed on the return side of the conveyor belt, offering valuable assistance in effectively dislodging and removing fine-grained or powdery materials that tend to adhere to the surface of the belt. This specialized roller contributes to maintaining a clean belt surface, thereby optimizing the overall conveyor performance.

Return training Idler

The return training idler serves the critical function of automatically aligning belts and safeguarding the edges against damage resulting from misalignment. This idler is available in the positive action type, specifically designed for belts operating in a single direction. Its inherent mechanism ensures precise belt tracking, promoting optimal performance and minimizing the risk of belt edge-related issues.

Troughed Training Idler

The troughed training idler serves the critical function of automatically aligning belts and safeguarding the edges against damage resulting from misalignment. This idler is available in the positive action type, specifically designed for belts operating in a single direction. Its inherent mechanism ensures precise belt tracking, promoting optimal performance and minimizing the risk of belt edge-related issues.

Wing Pulley

A diverse range of materials, such as steel, nylon, ceramic, HOPE (High-Density Polyethylene), or UHMWPE (Ultra-High Molecular Weight Polyethylene), are readily available for selection. Furthermore, these materials can be further enhanced with galvanized or powder-coated finishes, offering additional protective measures and customization options for specific application requirements.

Bend Pulley

The bend pulley serves the essential purpose of redirecting the running direction of the conveyor belt. Its configuration can be further categorized based on its specific placement, including the tail pulley, take-up pulley, snub pulley, among others. These distinct designations correspond to the various positions in which the bend pulley is strategically positioned along the conveyor system.

Beater Roller

The beater roller is a valuable solution for combating the persistent challenge of adhesive material buildup on the return side of the conveyor belt. It is highly recommended to strategically position the beater roller as the initial return roller closest to the head pulley. This placement optimizes its effectiveness in effectively dislodging and removing sticky residues, thereby enhancing the overall performance and longevity of the conveyor system.

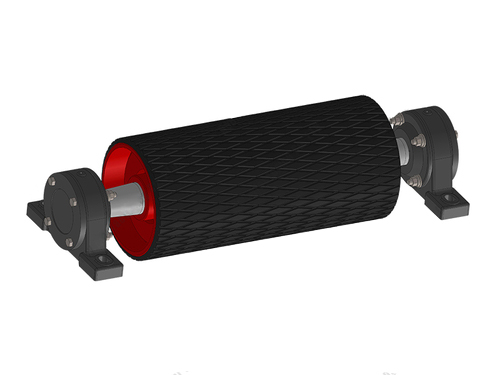

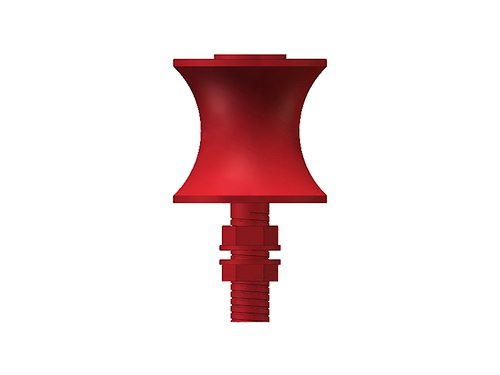

Rubber Coated Roller

The rubber coating on the roller is skillfully vulcanized directly, creating a robust and inseparable bond. This specialized rubber coating provides exceptional resistance against tearing, pounding, and friction, resulting in a significantly prolonged roller lifespan. The integration of rubber coating effectively safeguards against premature wear and tear, ensuring enhanced durability and longevity.

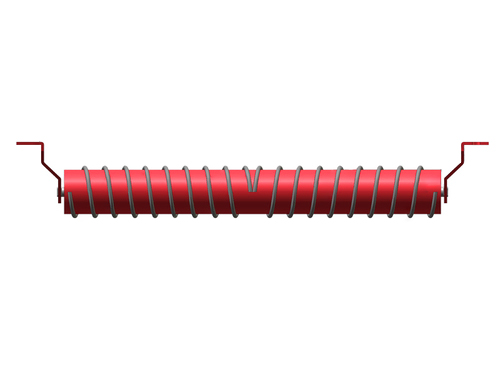

Spiral Roller

The spiral roller, positioned on the return side of the conveyor belt, serves as a highly efficient belt cleaner. This roller incorporates a spiral steel construction that acts akin to a screw, effectively pushing the accumulated material from the center towards the edges of the belt. Additionally, the spiral roller can also be manufactured with a spiral rubber variant, further enhancing its cleaning capabilities and overall operational effectiveness.

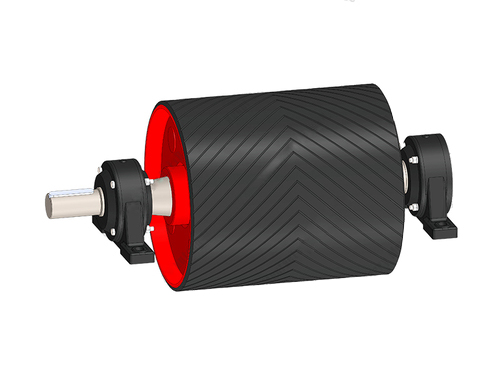

Drive Pulley

The drive pulley serves as the pivotal component responsible for transmitting power throughout the conveyor system. To enhance both the longevity of the pulley and its traction capabilities, it is commonly designed with a larger diameter compared to other pulleys. Depending on the specific carrying capacities required, the drive pulley can be categorized into three distinct classes: light duty, medium duty, and heavy duty. This classification system allows for optimal selection based on the varying operational demands and load requirements of the conveyor system.

Guide Roller

Vertical guide rollers provide practical benefits when installed on either side of the conveyor, or in conjunction with the trough rollers to provide additional support. These rollers serve the crucial purpose of facilitating the smooth and proper operation of material transport, ultimately leading to an improved self-aligning effect. Their presence significantly enhances the overall functionality and efficiency of the conveyor system.

Belt Cover

The conveyor cover is designed to provide protection against rain, dust, and wind. It ensures the safety and reliability of the conveyor belt’s operation while protecting the materials being conveyed from damage and maintaining the cleanliness of the surrounding environment. Typically, conveyor covers are made from galvanized steel or color-coated steel plates.

Our golas

Answer all your solutions for material handling products